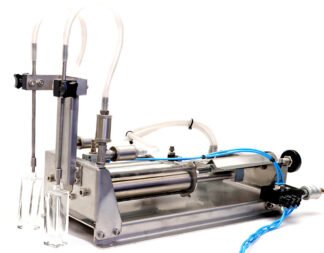

PLF-601 Volumetric Perfume Filling Machine

The PLF-601 Pneumatic Filler is a twin-head unit designed to dispense 10–100 ml of low-viscosity liquid per head with each stroke, with adjustable fill volumes. Similar to the PLF-600, it features semi-automatic operation. Whether the foot pedal is pressed briefly or held down, the machine will complete one full stroke per activation. During the cylinder recharging phase, filled bottles can be removed from beneath the nozzles and replaced with empty ones, ready for the next filling cycle.

Features

Fitted with an in-line 100-micron filter with a removable stainless steel element for easy cleaning.

Capable of filling 30 ml bottles at a rate of approximately 15–20 per minute, and 100 ml bottles at around 8–10 bottles per minute.

Built with a heavy-duty, all stainless steel frame.

Includes a setting gauge marked in 10 ml increments for simple and accurate stroke adjustment.

Stainless steel non-return valves can be dismantled for cleaning when required.

Filling and charging speeds can be adjusted independently for greater control.

Applications

This filler is suitable for a wide range of bottles and containers and is particularly well suited to plastic bottles, where vacuum filling systems may cause the bottle to partially collapse. It can handle most low-viscosity liquids and has been specifically designed for perfume filling.

Specifications

Dimensions: Length – 600 mm; Width – 280 mm; Height – 310 mm

Weight: 9.6 kg without foot pedal; 10.5 kg including foot pedal

Compressed air consumption at 6–8 bar pressure: Maximum 25 litres per minute

Construction materials: 304 stainless steel, aluminium, POM, and HDPE